Description

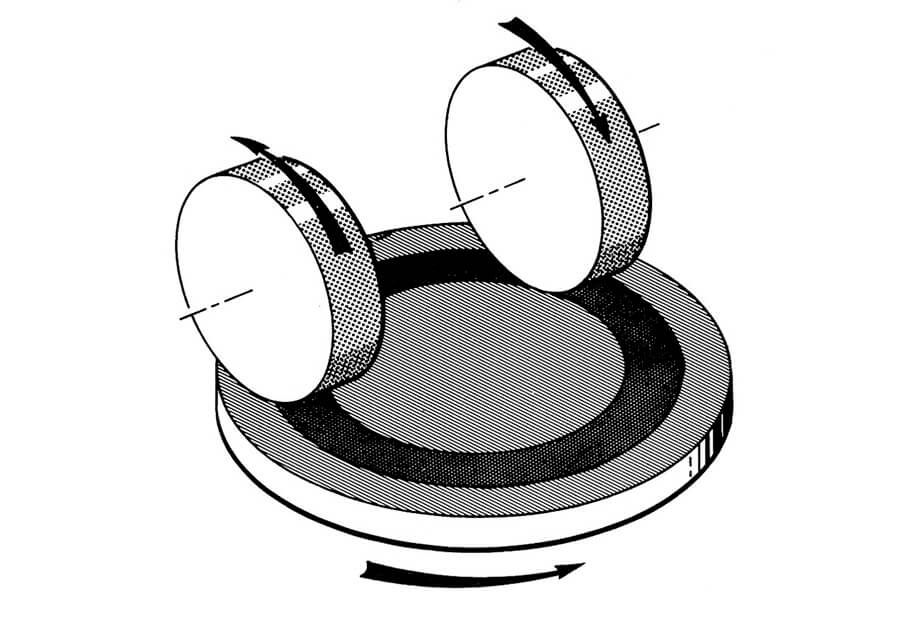

The Taber Abrasion Tester is Mounted to a rotating turntable, specimens are subjected to the rub-wear action of one or two abrasive wheels depending on the model. Driven by the test sample, the wheels produce abrasion marks that form a pattern of crossed arcs over a circular ring approximately 30 square centimeters. This reveals abrasion resistance at all angles relative to the weave or grain of the material.

The Taber Abraser is used to perform accelerated wear testing. Simple to use tester allows the collection of reliable data in a matter of minutes compared to the years that may be required by in-use testing. The Taber Abraser is used globally as the standard for evaluating abrasion resistance.

This instrument is used for quality & process control, research & development, and material evaluation. The Taber Abraser can be used to test virtually any flat specimen. This instrument has been referenced in numerous standards and specifications including plastics, coatings, laminates, leather, paper, ceramics, carpeting, safety glazing, and others.

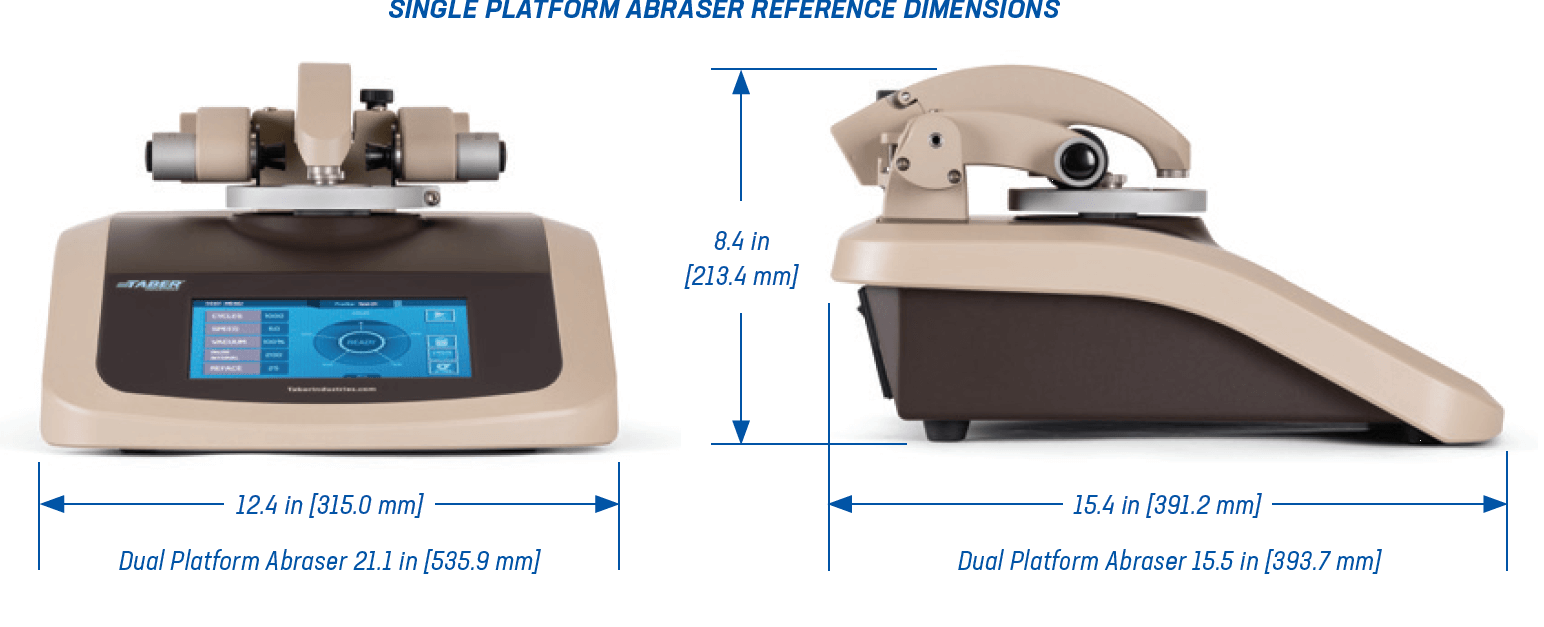

Model 1700 Single Platform Abraser (115/230V; 60/50Hz)

Single Specimen Turntable

Includes:

- (4) Auxiliary Weights provided (2) 500g & (2) 1000g load

- (1) Specimen Holder (SH-125)

- (1) Hold Down Ring (SH-101)

- (1) Vacuum Unit with Suction Hose (not shown)

(also referred to as Abraser (Abrader)or Rotary Platform Dual (Double) Head Tester)

NOTE: Replaces the Model 5135 – Single Platform Abraser and the Model 5155 – Dual Platform Abraser

Also Available – Model 1750 Single Platform Abraser