Descripción

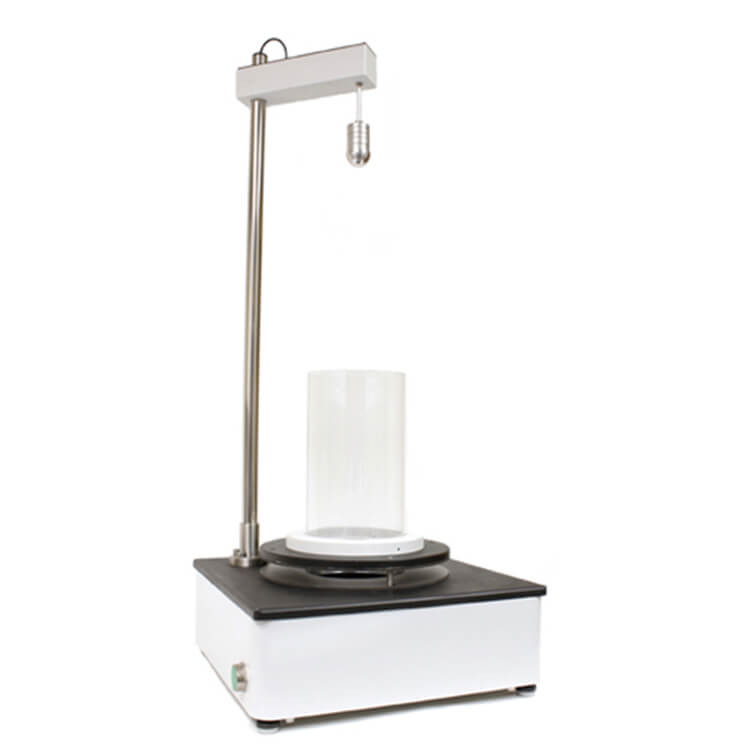

The dart drop tester is an easy-to-use, ergonomically designed instrument used to measure the impact resistance of plastic film, coated paper and other materials utilizing the free falling dart method.

How it Works

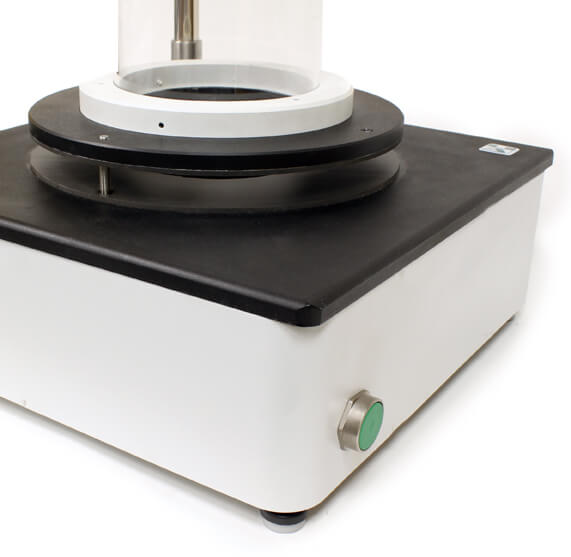

A pneumatic sample clamp is used to secure the specimen in place for ease of operation and operator safety. The operator needs to simultaneously activate dual switches mounted on either side of the instrument to engage the clamp and initiate the free falling dart. In addition, the dart drop tester provides a dual clamping sequence. The first phase utilizes low-pressure to safely clamp the sample followed by a high-pressure clamp prior to testing. The final phase of the test is completed with an automatic dart release.

ASTM D1709 – Method A

Dart 38.1 mm diameter

Drop height .66 m (26 in)

Dimensions (W x D x H)

41 cm x 41 cm x 120 cm (16 in x 16 in x 47 in)

Weight

18 kg (40 lbs)

ASTM D1709 – Method B

Dart 50.8 mm diameter (stainless steel)

Drop height 1.524 m (60 in)

Dimensions (W x D x H)

41 cm x 41 cm x 206 cm (16 in x 16 in x 81 in)

Dart Options

Phenolic head: 38.1 mm (1.5 in) diameter, 50 g

Aluminum head: 38.1 mm (1.5 in) diameter, 50 g

Stainless Steel head: 50.8 mm (2 in) diameter, 300 g

This instrument can also meet ASTM D5628 – Geometry FB (please note that you are meeting this standard when requesting a quotation)