How to Choose a Compression Platen

Choosing the right compression platen is crucial for accurate testing. Typically, samples are secured using upper and lower platens, as mandated by many common industry standards. We offer a variety of platen sizes to accommodate different sample dimensions, along with specialized platens for unique testing needs.

Compression Testing Fixtures From Thwing-Albert

Corrugated Board Crush Tester

The corrugated board crush tester features a pair of compression platens that perform flatwise and edgewise compression tests. The guide blocks hold the sample during testing. Its capacity is 5 kilonewton (kN), and it can support samples at a maximum width of 120 mm and a maximum thickness of 75 mm.

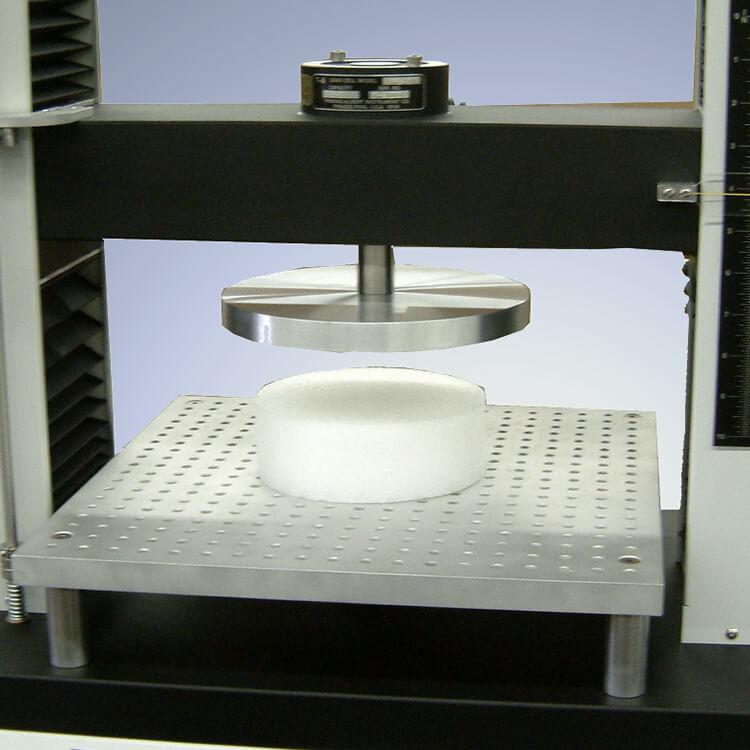

Foam Compression Fixture

The foam compression fixture measures compression force deflection (CFD) and indention force deflection (IFD) of expanded cellular materials. The fixture uses an upper compression plate and a perforated lower platform to allow rapid air escape during testing. It complies with ASTM 3574 and has a 10 kN capacity.

Circular Aluminum/Steel Compression Platen

The TA23 compression platen is for use in general compression tests on samples. The concentric circles platen assists in sample placement, enabling repeatable and accurate test results.

The TA23 aluminum platen is designed for soft samples, cardboards and plastics, and the TA23 steel platen tests hard materials, stone, steel and plastics. Both models comply with TAPPI T825 and ASTM D3574. With additional accessories, both models can comply with T821, T822 and T824.

Square Aluminum/Steel Compression Platen

The TA36 square compression platen tests the compressibility of soft and hard materials. The aluminum platens are used for soft samples such as cardboard and soft plastics, and the steel platens are used for hard materials such as hard plastics, stone and steel. Perforated compression platens are also available to test foam materials.

Crush Fixtures

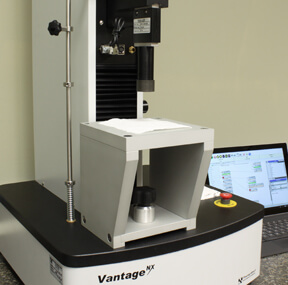

The TAS 733-200 crush fixture assists with flat crush, Concora crush, edge crush, pin adhesion and ring crush tests. The guided platen design ensures the sample complies with lateral movement and parallelism standards, including ISO 3037-2013, ISO 12192-Fig1, TAPPI T822 and TAPPI T811. It is designed to be used with a tensile tester, such as the VantageNX Tensile Testing Machine.

Vantage Compression Tester/Softness/Tissue Tester

The Vantage compression, softness and tissue tester instrument objectively measures material compressibility, loft and thickness to determine its softness. This computer-controlled instrument uses the latest technology and controls for advanced testing. This tester can be used with sheet materials such as textiles, nonwovens, toweling and paper tissue.

Contact Thwing-Albert for Compression Testing Fixtures

Thwing-Albert has over 125 years of experience in instrumentation for various test methods. We have the fixtures your operations need and can assist in finding the correct fixture for your test procedure and sample. Contact us for a free quote or more information today.